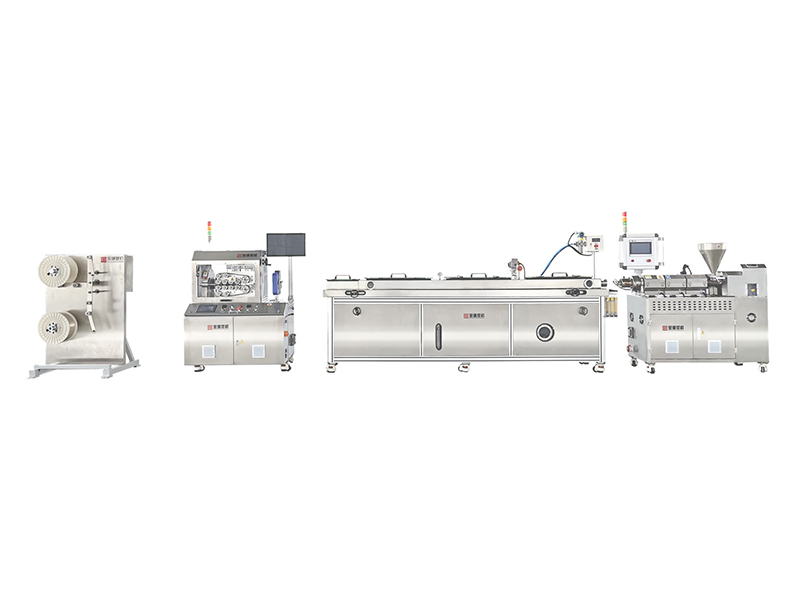

Ozi ngwaahịa

Dabere na ahụmahụ bara ụba bara uru na teknụzụ Japanese, anyị emepụtala ahịrị ahịrị nke atọ PA nkenke tube extrusion, nke ndị ahịa anyị nabatara n'ụlọ na mba ọzọ.

Ndị ọrụ njedebe anyị: CHINAUST Group, Sanoh Industrial, Arkema, HUATE Group, wdg.

Anyịuru

Njirimara akụrụngwa

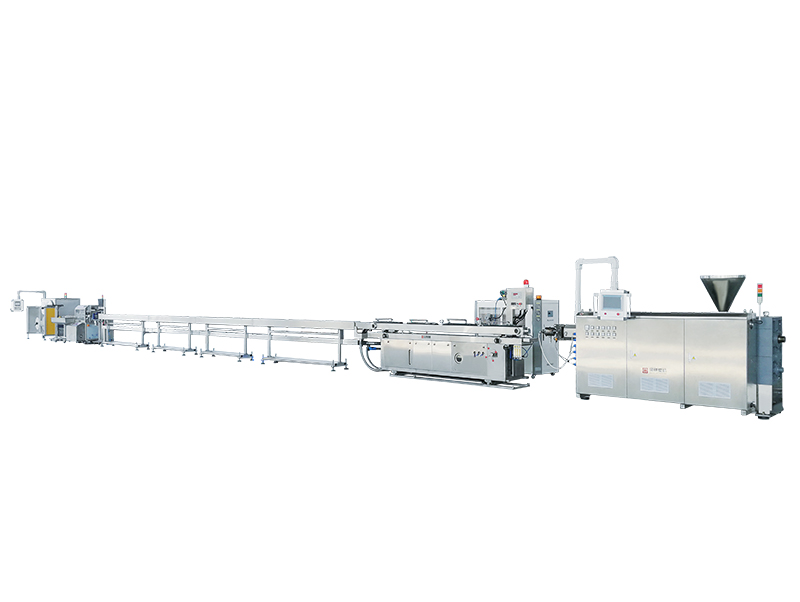

- PA (nylon) ịghasa bụ DSBM-T MADDOCK mgbochi ụdị agwakọta ebugharị ịghasa nke nwere ike n'ụzọ zuru okè imeghari ka ihe PA nke bụ na elu thermal uche, flowability na agbaze viscosity, si otú huu edo plasticization na elu mmepụta arụmọrụ;

- Mkpa mkpara na-anwụ anwụ bụ nke Sweden "ASSAB" S136 anwụ ígwè, nkenke egweri, nke ana achi achi esịtidem eruba elu glossiness na mgbochi corrosion. Ọdịdị nke ebu na-anabata "ụdị volumetric nrụgide dị elu", nke ụlọ ọrụ anyị malitere, nwere ike inye ọkụ siri ike na nke dị elu maka ihe tube na obere mgbanwe;

- Site na teknụzụ ọhụrụ nke "njikwa ziri ezi na-akpaghị aka nke oghere": oghere na usoro mmiri na-achịkwa iche iche. N'ụzọ dị otú a, anyị nwere ike na-ahazi multi-larịị mmiri nguzozi njikwa usoro na agụụ usoro, na-ahụ na ike agụụ agụụ, jụrụ mmiri larịị na mmiri eruba.

- Sistemụ nlele Laser arụmọrụ dị elu, na-eme njikwa nzaghachi mechiri emechi, na-ewepụ ngbanwe dayameta na ntanetị;

- Puller nwere eriri synchronous multilayer wear-na-eguzogide, na-enweghị ihe na-amị amị. Ọkwa dị elu nke ọma roller drive traction, YASKAWA Servo sistemu ịnya ụgbọ ala ma ọ bụ sistemụ ịnya ụgbọ ala ABB AC, na-amata ịdọ aka na ntị kwụsiri ike.

- Dabere na Servo ịnya ụgbọ ala usoro, Japan Mitsubishi PLC programmable njikwa na SIEMENS mmadụ kọmputa interface, cutter nwere ike na-aghọta nkenke na-aga n'ihu ọnwụ, oge igbutu, ogologo agụta igbutu wdg Ịcha ogologo nwere ike ịtọ n'efu, na ọnwụ oge nwere ike ịtọ na-akpaghị aka, nke nwere ike izute dị iche iche ọnwụ chọrọ nke dị iche iche ogologo.

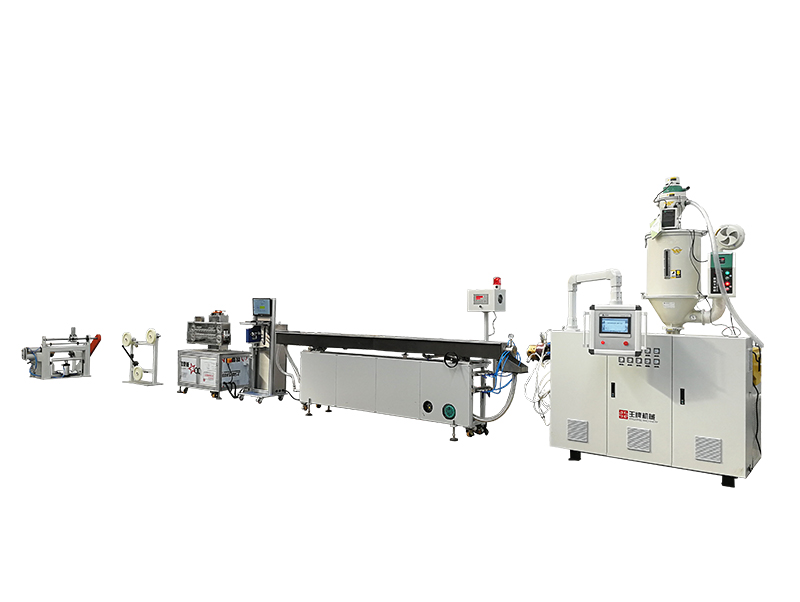

Nwuo

Aka aka calibration

Mmanụ na-ekpo ọkụ tank

Ihe nlele laser

Puller na cutter

tankị mkpokọta

Igwe ikuku

Isi Nka na ụzụ Parameter

| Nlereanya | Ogologo dayameta ọkpọkọ usoro (mm) | Dayameta ịghasa (mm) | L/D | Isi ike (KW) | Nsonaazụ (Kg/h) |

| SXG-45 | 3.0 ruo 12.0 | 45 | 30 | 15 | 18-30 |

| SXG-50 | 3.0 ruo 16.0 | 50 | 30 | 18.5/22 | 28-45 |

| SXG-65 | 3.0-20.0 | 65 | 30 | 37/45 | 55-85 |

| SXG-75 | 3.0-20.0 | 75 | 30 | 55/75 | 80-110 |

Nkọwapụta nke PA Obere Tube na Nkọwa Ọnọdụ Mmepụta

| OD (mm) | Na-emepụta ọsọ(m/min) | Izi ezi njikwa dayameta(≤mm) |

| 4.0 | 80-100 | ±0.05 |

| 6.0 | 60-80 | ±0.05 |

| 8.0 | 40-50 | ±0.08 |

| 10.0 | 25-40 | ±0.08 |

| 12.0 | 16-30 | ±0.10 |

| 14.0 | 12-20 | ±0.10 |

| 16.0 | 10-15 | ±0.12 |

Ntụtụ aka nke ịkpụzi

| Ogologo ịkpụ | ≤50mm | ≤500mm | ≤1000mm | ≤2000mm |

| Ịcha izi ezi | ± 0.5mm | ± 1.0mm | ± 2.0mm | ± 3.0mm |